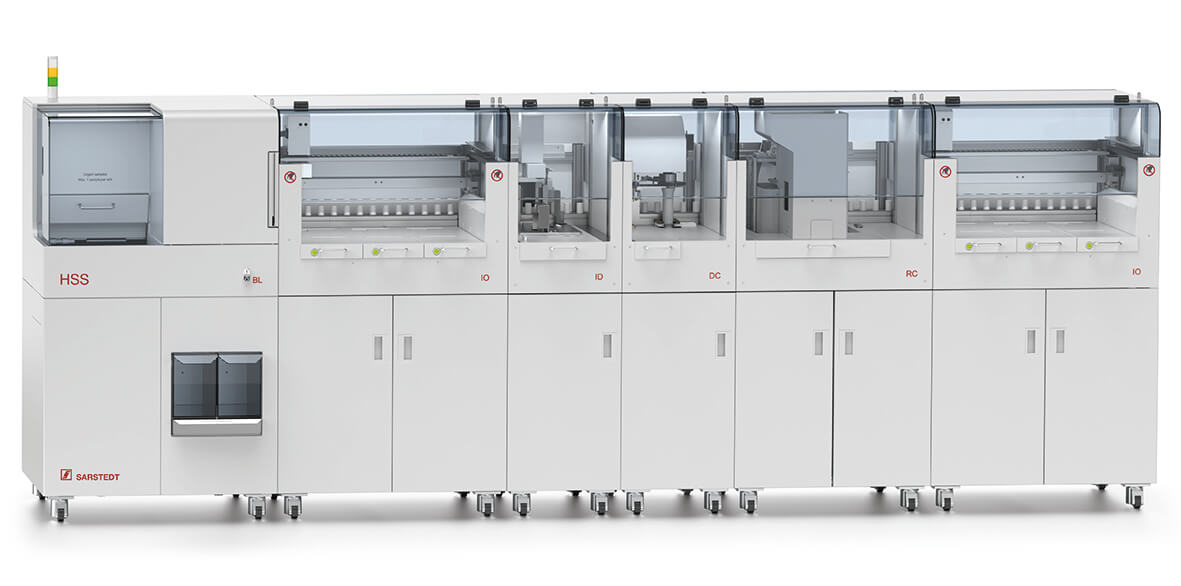

The new High Speed Sorter HSS is assembled from modules according to customer specifications and thus tailored exactly to the requirements of the respective laboratory environment. The following modules are available:

- BL Module

Feeding of closed sample tubes in bulk without pre-sorting and insertion into racks. The BL Module has an integrated ID Module to identify the samples, capture the tube type (cap color, shape and tube geometry), and to determine the centrifugation status (Gel-Check).

- IO Module

The IO Module is used to load or unload open or capped sample tubes in the rack. The platform layout is created laboratory-specific and can be variably adapted with FlexPlates, e.g. for switching between routine and archive runs.

- ID Module

The ID Module identifies sample tubes via the barcode, captures the tube type (cap color, shape and tube geometry) and determines the centrifugation status (Gel-Check).

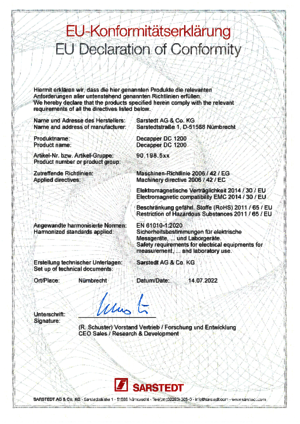

- DC Module

The decapper opens tubes with screw caps or stoppers from different manufacturers in preparation for analysis.

- RC Module

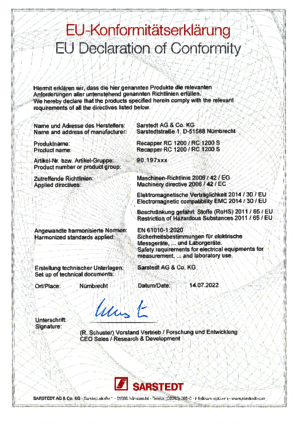

The Recapper is available in 3 versions. It closes sample tubes of 13 - 16 mm diameter with a universal cap and thus prevents evaporation. Alternatively, SARSTEDT tubes with 13 or 15 mm diameter are closed with the matching screw cap for transport or long-term archiving.

- SC Module

The SortConnect Module enables the HSS to be connected to an analysis line. Manual transfer of individual tubes or tubes in the rack is no longer necessary. The workflow is continuous and saves time.

• Full function pre- and post-analytical system

• Ideal in combination with any analytical platform

• Modular configuration according to customer needs with:

o Loading platform and/or Bulk Loader

o ID Module

o Decapper

o Recapper

o Aliquoter

o Sorter

• For all common tube types

o 13–16 mm diameter

o 65–100 mm length

• Compatible with most racks or carrier types

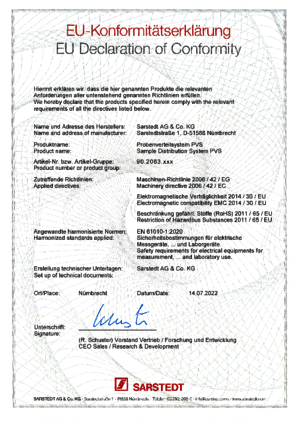

The PVS 1625 is a tailor made automation system for pre- and post-analytical processing of samples. It is able to handle any kind of rack and tray type. As an open system, it is complementary to any analytical platform or can be used independently.

The sample tubes are fed in bulk via the Bulk Loader Module or in racks via the Loader platform. Thus, closed and open tubes can be processed equally.

The ID Module reads the barcode and captures the tube type (cap color, shape, tube geometry).

Barcoded secondary tubes are prepared and the requested volume is dispensed at the Aliquoter. No more sample mix-ups will occur and the available volume will be used in the most efficient way.

There are two versions of recapper modules for archiving or for sending samples. Tubes are either closed with an archiving cap (all diameters from 13–16 mm) or with a screw cap (Sarstedt tubes with a diameter of 13 or 15 mm, e.g. S-Monovette®).

Closed samples are loaded by feeding them into the Bulk Loader module. Just dump the specimen tubes into the bulk loader – no sorting or handling required.

Alternatively, open or closed sample tubes can be placed in any rack or tray on the loading platform and fed into the system from there.

Using the FlexPlate provides the maximum number of options for sample carriers.

Identification

Each tube must be identified by the barcode for targeted sample distribution. The barcode can also contain information about the type of sample material. Lastly, the tube type plays an important role to ensure trouble-free processing. The ID Module reads the barcode, captures the tube type (cap color, shape, tube geometry) and determines for gel tubes with Gel-Check the centrifugation status. This is done via a two-stage process with camera and laser sensor.

• Barcode

• Tube type

o Length

o Diameter

o Cap colour and shape

• Centrifugation status (Gel-Check)

Decapping

The decapper module opens screw cap and stopper tubes. All tubes from 13–16 mm in diameter and 80–110 mm in length (including the cap) are processed in a mixed operation without pre-sorting (different sizes upon request). The stoppers and screw caps are safely removed and hygienically disposed of.

• Stopper

• Screw cap

Aliquoting

The aliquoter prepares barcoded secondary tubes and dispenses the required volumes into them. Sample mix-ups are eliminated and the available sample amount will be used in the most efficient way.

Recapping

There are two versions of recapper modules available. Tubes are either closed with a universal stopper for all diameters from 13–16 mm, or with a screw cap for Sarstedt tubes (e.g. S-Monovette®) with a diameter of 13 or 15 mm.

Sorting/Archiving

The sample tubes are sorted according to analysis requests from the LIS (laboratory information system) or according to strict distribution rules, e.g. cap colour. All existing rack and carrier systems can be used (see also FlexPlate). For the Bulk Loader BL 2000, tubes are sorted into bins for individual working areas.

Gel-Check

Hello digital! Digitalise your pre-analytics

Hello digital! Digitalise your pre-analytics

Language:

AL-Flex

AL-Flex

Language:

HCTS 2000 MK2

HCTS 2000 MK2

Language:

BL 1200 Sort Connect

BL 1200 Sort Connect

Language:

We would like to show you additional content which is hosted by a third party. For this purpose we need your consent to set cookies:

Sample Distribution System PVS

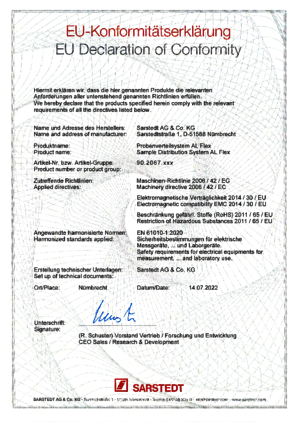

Sample Aliquoting System AL-Flex

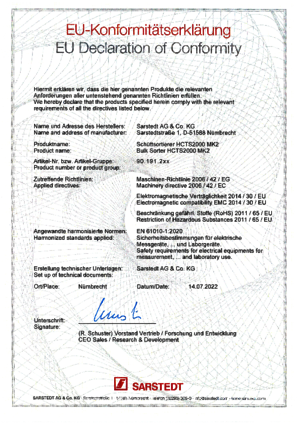

Bulk Sorter HCTS2000 MK2

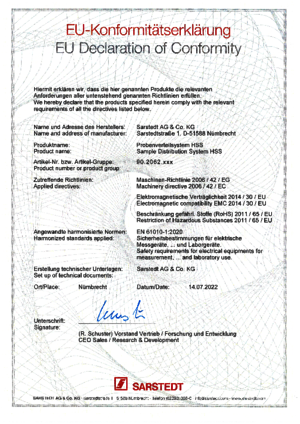

Sample Distribution System HSS

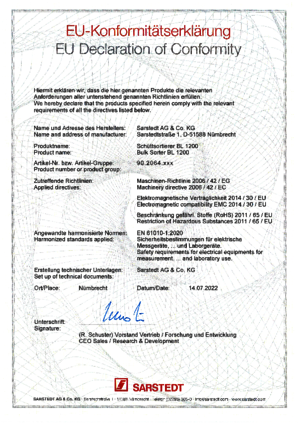

Bulk Sorter BL 1200

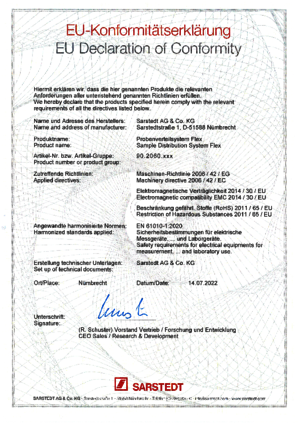

Sample Distribution System Flex

Recapper RC 1200 / Recapper 1200 S